Essential Insights into Borehole Drilling Equipment for Efficient Construction

Nov 09,2025

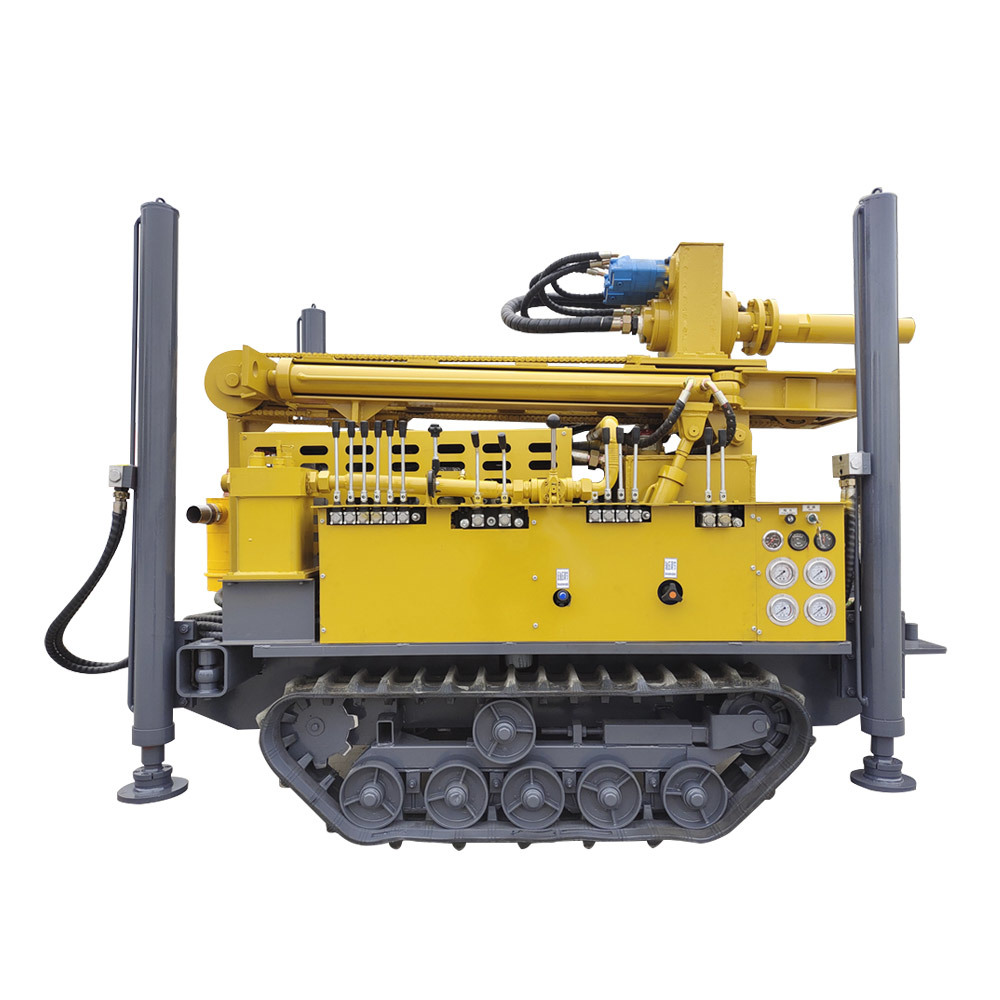

Borehole drilling equipment is an essential component in the construction and engineering sectors, particularly for projects that require precise subsurface exploration. Understanding the types and applications of this equipment can significantly enhance operational efficiency and ensure project success.

At its core, borehole drilling equipment is designed to create deep, narrow holes in the ground, which can be utilized for various purposes such as water extraction, geological surveys, and environmental monitoring. The equipment used for these tasks ranges from basic hand-operated drills to sophisticated, heavy-duty machinery capable of reaching significant depths.

One common type of borehole drilling equipment is the rotary drill. This machine operates using a rotating drill bit that cuts through various soil and rock types. Rotary drills are often employed in both shallow and deep drilling applications, making them versatile for different project requirements. They are particularly effective in areas with hard rock formations, where traditional drilling methods may falter.

Another prevalent type of borehole drilling equipment is the percussion drill. This equipment works by delivering rapid blows to the drill bit, breaking the material into smaller pieces that can then be removed from the borehole. Percussion drilling is advantageous in softer soils and is often used in mineral exploration and geotechnical investigations.

In addition to the type of drill, it is crucial to consider the accessories and support equipment that can enhance drilling operations. For example, mud pumps are often used in conjunction with drilling rigs to circulate drilling fluid, which helps to cool the drill bit and remove cuttings from the borehole. Proper management of drilling fluids is vital, as it can prevent complications such as borehole collapse and improve overall drilling efficiency.

Safety is another paramount concern when operating borehole drilling equipment. Operators should be well-trained in the use of machinery and adhere to safety protocols to minimize risks on the job site. Regular maintenance of equipment is also essential in ensuring reliability and extending the lifespan of the machinery.

In conclusion, borehole drilling equipment plays a pivotal role in modern construction and engineering projects. By understanding the different types of equipment available and implementing best practices for their use, professionals can optimize their drilling operations, ensuring successful outcomes in their projects. Whether for water well drilling, mineral exploration, or environmental studies, the right borehole drilling equipment is integral to achieving operational excellence.

At its core, borehole drilling equipment is designed to create deep, narrow holes in the ground, which can be utilized for various purposes such as water extraction, geological surveys, and environmental monitoring. The equipment used for these tasks ranges from basic hand-operated drills to sophisticated, heavy-duty machinery capable of reaching significant depths.

One common type of borehole drilling equipment is the rotary drill. This machine operates using a rotating drill bit that cuts through various soil and rock types. Rotary drills are often employed in both shallow and deep drilling applications, making them versatile for different project requirements. They are particularly effective in areas with hard rock formations, where traditional drilling methods may falter.

Another prevalent type of borehole drilling equipment is the percussion drill. This equipment works by delivering rapid blows to the drill bit, breaking the material into smaller pieces that can then be removed from the borehole. Percussion drilling is advantageous in softer soils and is often used in mineral exploration and geotechnical investigations.

In addition to the type of drill, it is crucial to consider the accessories and support equipment that can enhance drilling operations. For example, mud pumps are often used in conjunction with drilling rigs to circulate drilling fluid, which helps to cool the drill bit and remove cuttings from the borehole. Proper management of drilling fluids is vital, as it can prevent complications such as borehole collapse and improve overall drilling efficiency.

Safety is another paramount concern when operating borehole drilling equipment. Operators should be well-trained in the use of machinery and adhere to safety protocols to minimize risks on the job site. Regular maintenance of equipment is also essential in ensuring reliability and extending the lifespan of the machinery.

In conclusion, borehole drilling equipment plays a pivotal role in modern construction and engineering projects. By understanding the different types of equipment available and implementing best practices for their use, professionals can optimize their drilling operations, ensuring successful outcomes in their projects. Whether for water well drilling, mineral exploration, or environmental studies, the right borehole drilling equipment is integral to achieving operational excellence.