The Essential Guide to Borehole Drilling Equipment: Unlocking the Secrets of Efficient Water and Resource Extraction

Sep 12,2025

Borehole drilling equipment is a vital component in numerous industries, including water resource management, mining, and geothermal energy. Understanding the intricacies of this equipment can significantly enhance its effectiveness and longevity.

At its core, borehole drilling refers to the process of creating deep holes in the ground to access natural resources, such as groundwater or minerals. The equipment used in this process is specialized and designed to handle the unique challenges associated with drilling into various types of soil and rock formations.

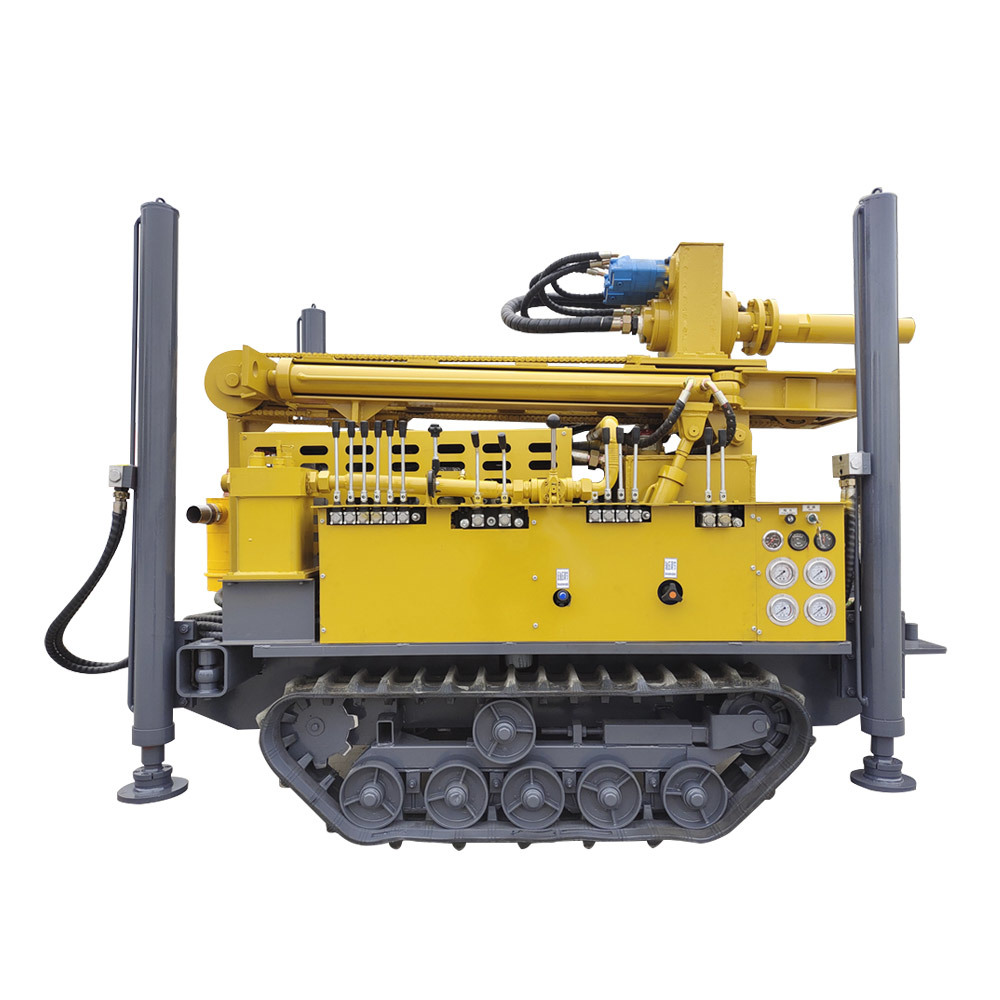

One of the primary types of borehole drilling equipment is the rotary drilling rig. This machine employs a rotating drill bit that grinds through rock and soil, creating a vertical hole. Rotary rigs are particularly popular due to their versatility and ability to drill deep into the earth, making them suitable for both small-scale and large-scale projects.

Another critical component of borehole drilling equipment is the drill pipe. This hollow tube connects the drill bit to the rig and serves as a conduit for drilling fluids. These fluids, often referred to as drilling mud, are essential for cooling the drill bit, removing cuttings from the borehole, and stabilizing the walls of the hole. The type of drilling fluid used can vary based on the geological conditions encountered during drilling.

Additionally, downhole tools, such as casing and screens, play a crucial role in borehole drilling processes. Casing is used to line the borehole, preventing collapse and protecting the water or mineral resource from contamination. Screens are often installed to filter out debris while allowing water to flow freely into the borehole.

In recent years, advancements in technology have led to innovative developments in borehole drilling equipment. For instance, automated drilling systems are now available, which can significantly reduce human error and improve safety on drilling sites. These systems utilize advanced sensors and software to monitor and control the drilling process, ensuring optimal performance.

Moreover, the environmental impact of borehole drilling is an important consideration. Modern equipment is designed to minimize ecological disruption, utilizing techniques that reduce noise and limit the footprint of drilling operations. Sustainable practices, such as responsible water use and waste management, are also increasingly integrated into the borehole drilling process.

In conclusion, understanding borehole drilling equipment and its various components is essential for anyone involved in resource extraction or environmental management. Whether you are drilling for water, minerals, or energy, having the right equipment and knowledge can make a significant difference in achieving successful outcomes. Investing in quality borehole drilling equipment and staying informed about best practices will not only increase efficiency but also ensure the sustainability of our precious natural resources.

At its core, borehole drilling refers to the process of creating deep holes in the ground to access natural resources, such as groundwater or minerals. The equipment used in this process is specialized and designed to handle the unique challenges associated with drilling into various types of soil and rock formations.

One of the primary types of borehole drilling equipment is the rotary drilling rig. This machine employs a rotating drill bit that grinds through rock and soil, creating a vertical hole. Rotary rigs are particularly popular due to their versatility and ability to drill deep into the earth, making them suitable for both small-scale and large-scale projects.

Another critical component of borehole drilling equipment is the drill pipe. This hollow tube connects the drill bit to the rig and serves as a conduit for drilling fluids. These fluids, often referred to as drilling mud, are essential for cooling the drill bit, removing cuttings from the borehole, and stabilizing the walls of the hole. The type of drilling fluid used can vary based on the geological conditions encountered during drilling.

Additionally, downhole tools, such as casing and screens, play a crucial role in borehole drilling processes. Casing is used to line the borehole, preventing collapse and protecting the water or mineral resource from contamination. Screens are often installed to filter out debris while allowing water to flow freely into the borehole.

In recent years, advancements in technology have led to innovative developments in borehole drilling equipment. For instance, automated drilling systems are now available, which can significantly reduce human error and improve safety on drilling sites. These systems utilize advanced sensors and software to monitor and control the drilling process, ensuring optimal performance.

Moreover, the environmental impact of borehole drilling is an important consideration. Modern equipment is designed to minimize ecological disruption, utilizing techniques that reduce noise and limit the footprint of drilling operations. Sustainable practices, such as responsible water use and waste management, are also increasingly integrated into the borehole drilling process.

In conclusion, understanding borehole drilling equipment and its various components is essential for anyone involved in resource extraction or environmental management. Whether you are drilling for water, minerals, or energy, having the right equipment and knowledge can make a significant difference in achieving successful outcomes. Investing in quality borehole drilling equipment and staying informed about best practices will not only increase efficiency but also ensure the sustainability of our precious natural resources.

PREVIOUS: