The Importance of Training for Mini Water Borehole Rig Operators: Ensuring Safety and Efficiency

Sep 16,2025

The Importance of Training for Mini Water Borehole Rig Operators

Introduction to Mini Water Borehole Rigs

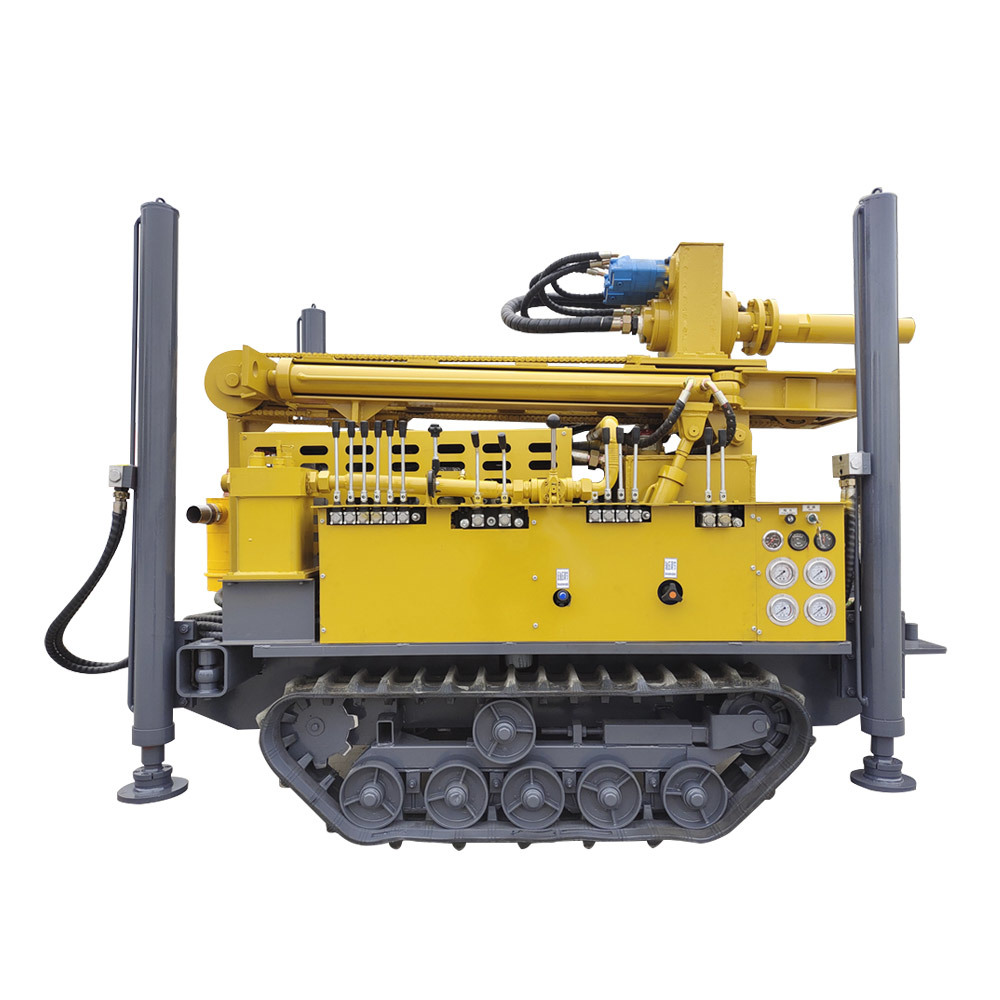

The emergence of mini water borehole rigs has revolutionized the drilling industry, allowing for efficient and precise water extraction. These compact and versatile machines are increasingly favored for agricultural, construction, and environmental projects. However, the complexity of operating a mini water borehole rig necessitates comprehensive training for operators. Proper training not only ensures productivity but also enhances safety and extends the longevity of the equipment.

Understanding the Role of a Mini Water Borehole Rig Operator

Mini water borehole rig operators are responsible for the installation and maintenance of boreholes that provide access to groundwater. Their role is crucial in various sectors, including:

- **Agriculture**: Providing irrigation solutions to optimize crop yield.

- **Construction**: Supplying water for mixing concrete and other construction processes.

- **Environmental Studies**: Facilitating groundwater sampling and monitoring.

Understanding these roles lays the groundwork for appreciating why training is indispensable.

The Risks Involved in Operating Mini Water Borehole Rigs

Operating mini water borehole rigs presents inherent risks. These include:

- **Equipment Malfunction**: A well-trained operator can identify potential mechanical issues before they escalate.

- **Environmental Hazards**: Awareness of environmental regulations is essential to prevent contamination.

- **Personal Safety**: Operators face risks from heavy machinery, requiring knowledge of safety protocols.

Proper training equips operators with the skills needed to mitigate these risks effectively.

The Benefits of Comprehensive Training Programs

Investing in training programs for mini water borehole rig operators yields numerous benefits, including:

1. Enhanced Safety Standards

Safety is paramount in any operational environment. A structured training program empowers operators with the knowledge of best practices, safety protocols, and emergency procedures, significantly reducing the likelihood of workplace accidents.

2. Increased Operational Efficiency

Trained operators are more efficient and productive. They can execute tasks quickly and correctly, reducing downtime and maximizing output. This efficiency translates to lower operational costs and increased project profitability.

3. Skill Development and Technical Knowledge

Training fosters a deeper understanding of equipment mechanics, troubleshooting, and maintenance. This knowledge allows operators to perform basic repairs and recognize when professional help is needed, minimizing interruptions.

4. Compliance with Industry Standards

Many regions have specific regulations governing borehole drilling. Training ensures operators are familiar with these regulations, helping their organizations remain compliant and avoid costly fines.

5. Enhanced Reputation and Customer Trust

Businesses with well-trained operators tend to build a better reputation within the community and industry. Clients are more likely to trust companies that prioritize safety and operational excellence, leading to increased business opportunities.

Components of Effective Training Programs for Mini Water Borehole Rig Operators

Creating an effective training program involves several key components:

1. Theoretical Knowledge

Training should cover the theoretical aspects of borehole drilling, including geology, hydrology, and equipment mechanics. This foundational knowledge enables operators to understand the complexities of their tasks.

2. Practical Skills Development

Hands-on training is essential. Operators should receive real-world experience under the supervision of seasoned professionals. This practice allows them to apply their theoretical knowledge in practical situations.

3. Safety Protocols and Emergency Procedures

Training must emphasize safety protocols, including the use of personal protective equipment (PPE), safe lifting techniques, and emergency response actions in case of accidents.

4. Equipment Familiarization

Operators should be thoroughly familiarized with the specific mini water borehole rig they will be using. This includes understanding controls, maintenance procedures, and troubleshooting common issues.

5. Continuous Education and Certification

Ongoing training ensures that operators remain up-to-date with the latest industry practices and technology advancements. Certification programs can validate their skills and knowledge.

Training Methods and Techniques for Operators

Various methods can be employed to ensure effective training delivery:

1. Classroom Learning

Formal lectures and presentations provide a structured environment for theoretical education. Utilizing visual aids such as videos and diagrams enhances understanding.

2. Hands-On Workshops

Practical workshops allow operators to engage with the equipment in a controlled setting. This interactive approach reinforces learning and builds confidence.

3. Online Training Modules

Incorporating online learning platforms can provide flexibility. Operators can complete modules at their own pace, making training accessible even for remote teams.

4. On-the-Job Training

Shadowing experienced operators during actual drilling operations offers invaluable insights. New operators can learn best practices and troubleshooting techniques in real-time.

5. Simulation-Based Training

Advanced simulation technology can create realistic drilling environments where operators can practice their skills without the risks associated with actual operations.

Measuring the Effectiveness of Training Programs

To ensure training programs are effective, it is essential to employ various metrics:

1. Operator Performance Assessments

Conduct regular assessments to evaluate operators' skills and knowledge. This can be done through practical exams or written tests.

2. Safety Incident Tracking

Monitor the frequency of safety incidents before and after training. A decrease in incidents indicates improved safety practices.

3. Feedback Mechanisms

Collect feedback from participants regarding the training content and delivery. Use this information to refine and enhance future training sessions.

4. Productivity Metrics

Analyze project completion times and operational efficiency metrics pre- and post-training to determine the impact on productivity.

5. Certification Success Rates

Track the success rates of operators who complete certification programs. High pass rates can indicate the effectiveness of the training initiative.

Challenges in Training Mini Water Borehole Rig Operators

While training is crucial, several challenges may arise:

1. Resource Allocation

Training requires time and financial resources, which can be challenging for smaller organizations. It is essential to allocate a budget for training without compromising operational needs.

2. Resistance to Change

Some seasoned operators may resist new training, believing their experience suffices. Addressing this mindset is vital for fostering a culture of continuous learning.

3. Keeping Up with Technological Advancements

As technology evolves, training programs must adapt to include new tools and techniques. Regularly updating training content is necessary to stay current.

4. Customizing Training for Diverse Skills Levels

Operators may possess varying levels of experience and skill. Training programs must be tailored to accommodate these differences, ensuring all participants benefit.

Conclusion: The Critical Role of Operator Training in Borehole Drilling Success

The importance of training for mini water borehole rig operators cannot be overstated. Comprehensive programs enhance safety, increase operational efficiency, and ensure compliance with industry standards. By investing in training, organizations can improve their workforce's skills, leading to successful project outcomes and a strong reputation in the marketplace. Through continuous education and a commitment to safety, operators can harness the full potential of mini water borehole rigs, ultimately contributing to more sustainable water management practices.

Frequently Asked Questions (FAQs)

1. Why is training necessary for mini water borehole rig operators?

Training is essential to ensure safety, enhance operational efficiency, and comply with industry regulations.

2. What are the key components of an effective training program?

Key components include theoretical knowledge, practical skills development, safety protocols, equipment familiarization, and continuous education.

3. How can organizations measure the effectiveness of their training programs?

Effectiveness can be measured through performance assessments, safety incident tracking, feedback mechanisms, productivity metrics, and certification success rates.

4. What challenges might arise when implementing training programs?

Challenges include resource allocation, resistance to change, keeping up with technological advancements, and customizing training for diverse skill levels.

5. Are there different training methods suitable for mini water borehole rig operators?

Yes, suitable methods include classroom learning, hands-on workshops, online training modules, on-the-job training, and simulation-based training.