Essential Insights into Borehole Drilling Equipment for Engineering and Construction

Jan 11,2026

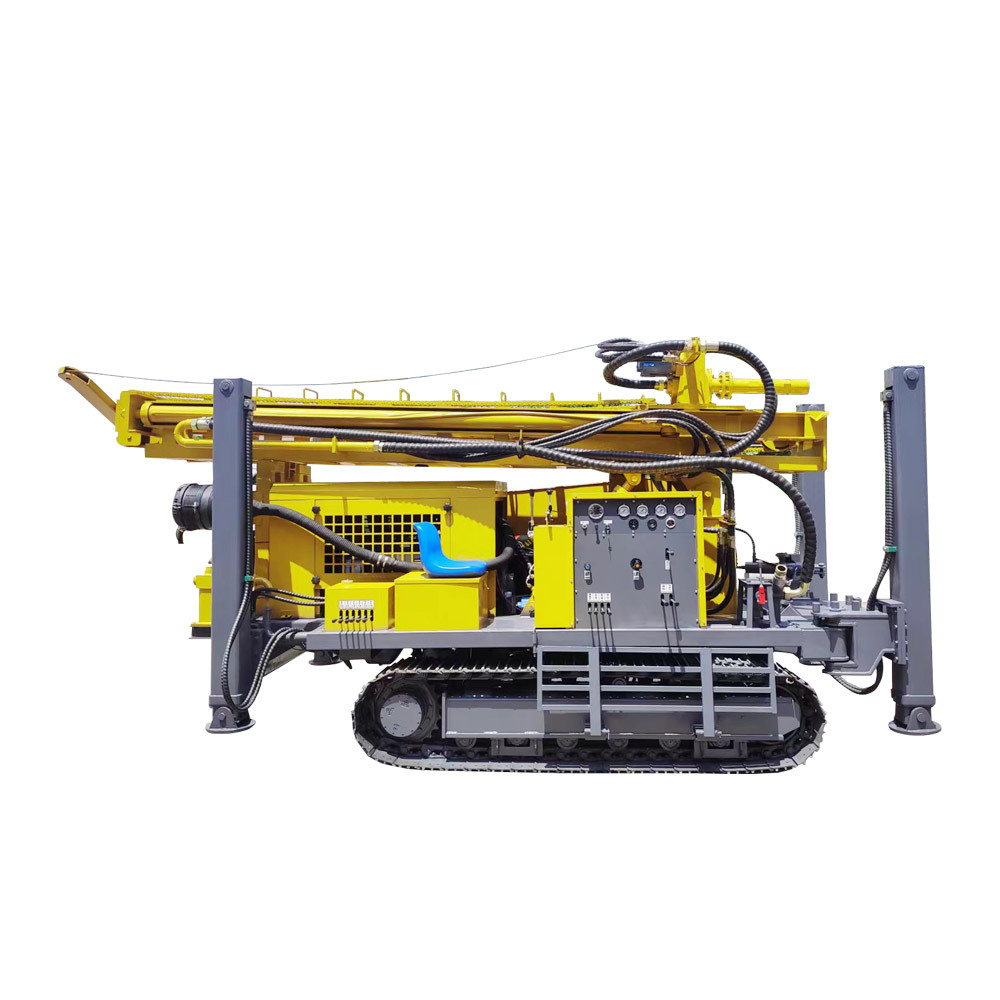

Borehole drilling equipment is essential in the realm of engineering and construction, serving a multitude of purposes from groundwater extraction to geothermal energy production. Understanding the various types of drilling equipment and their applications is crucial for any professional in the field. Here, we will provide a comprehensive overview of borehole drilling equipment, its functionality, and important considerations for effective usage.

There are several types of borehole drilling equipment, each designed for specific applications. The most common types include rotary drilling rigs, percussion drilling rigs, and auger drilling equipment. Rotary drilling rigs utilize a rotating drill bit to cut through the earth, making them suitable for deeper boreholes. These rigs are often equipped with advanced technologies that allow for precise control and efficient drilling in various soil types.

Percussion drilling rigs, on the other hand, operate by repeatedly lifting and dropping a heavy drill bit to break up the rock. This method is particularly effective in hard rock formations and is often used in mineral exploration. Auger drilling equipment utilizes a helical screw to excavate soil and is typically used for shallow boreholes, such as those required for environmental studies or groundwater monitoring.

When selecting the right borehole drilling equipment, several factors must be considered. Firstly, the geological conditions of the drilling site play a significant role. The type of soil and rock, as well as the depth of the borehole, will determine which equipment is most suitable. Additionally, the drilling method—whether rotary, percussion, or auger—should align with the project goals and expected outcomes.

Another critical aspect is the hydraulic system of the equipment. Borehole drilling often requires high-pressure systems to ensure efficient operation, especially in challenging terrains. Therefore, understanding the hydraulic capabilities of the drilling equipment is essential to achieving desired performance and minimizing downtime.

Safety is also a paramount concern when operating borehole drilling equipment. Operators must be trained to handle the machinery properly and be aware of the potential hazards associated with drilling activities. Regular maintenance and inspections should be conducted to ensure the equipment remains in optimal working condition and to prevent accidents on site.

In conclusion, borehole drilling equipment is a vital component in engineering and construction projects. Familiarity with the different types of drilling rigs, their functionalities, and the factors influencing equipment selection can significantly impact project success. By understanding these elements, professionals in the field can make informed decisions and enhance their operational efficiency, ultimately leading to more successful outcomes in their projects.

There are several types of borehole drilling equipment, each designed for specific applications. The most common types include rotary drilling rigs, percussion drilling rigs, and auger drilling equipment. Rotary drilling rigs utilize a rotating drill bit to cut through the earth, making them suitable for deeper boreholes. These rigs are often equipped with advanced technologies that allow for precise control and efficient drilling in various soil types.

Percussion drilling rigs, on the other hand, operate by repeatedly lifting and dropping a heavy drill bit to break up the rock. This method is particularly effective in hard rock formations and is often used in mineral exploration. Auger drilling equipment utilizes a helical screw to excavate soil and is typically used for shallow boreholes, such as those required for environmental studies or groundwater monitoring.

When selecting the right borehole drilling equipment, several factors must be considered. Firstly, the geological conditions of the drilling site play a significant role. The type of soil and rock, as well as the depth of the borehole, will determine which equipment is most suitable. Additionally, the drilling method—whether rotary, percussion, or auger—should align with the project goals and expected outcomes.

Another critical aspect is the hydraulic system of the equipment. Borehole drilling often requires high-pressure systems to ensure efficient operation, especially in challenging terrains. Therefore, understanding the hydraulic capabilities of the drilling equipment is essential to achieving desired performance and minimizing downtime.

Safety is also a paramount concern when operating borehole drilling equipment. Operators must be trained to handle the machinery properly and be aware of the potential hazards associated with drilling activities. Regular maintenance and inspections should be conducted to ensure the equipment remains in optimal working condition and to prevent accidents on site.

In conclusion, borehole drilling equipment is a vital component in engineering and construction projects. Familiarity with the different types of drilling rigs, their functionalities, and the factors influencing equipment selection can significantly impact project success. By understanding these elements, professionals in the field can make informed decisions and enhance their operational efficiency, ultimately leading to more successful outcomes in their projects.