Essential Insights into Borehole Drilling Equipment for Engineering and Construction

Feb 10,2026

Borehole drilling equipment plays a pivotal role in various engineering and construction applications, from geological surveys and water well installations to geothermal energy projects. Understanding the intricacies of this equipment is essential for professionals looking to optimize their drilling operations.

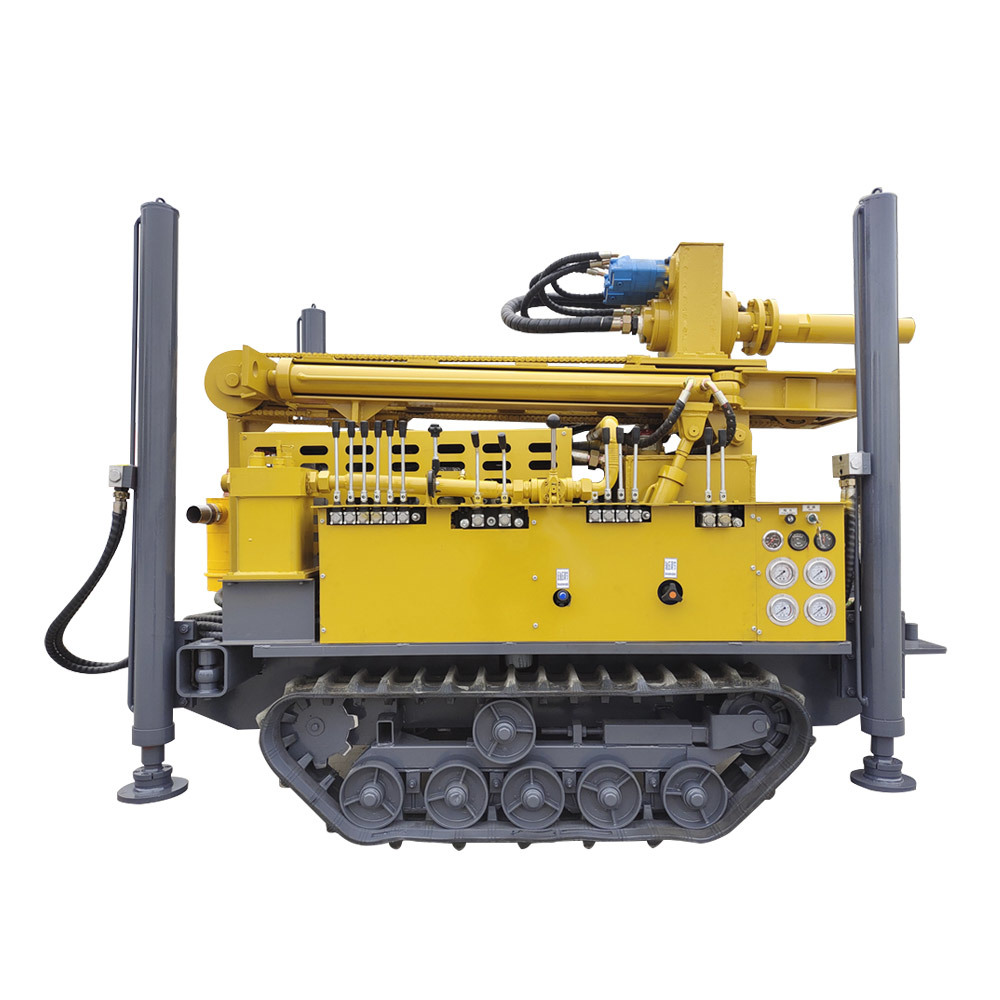

At its core, borehole drilling equipment is designed to penetrate various strata of the Earth, allowing for the extraction of natural resources, the assessment of geological formations, and the establishment of infrastructures like water wells. The equipment comes in a variety of types, including rotary drilling rigs, percussion drilling machines, and auger rigs, each suited for specific soil conditions and project requirements.

Rotary drilling rigs are among the most widely used in borehole drilling due to their efficiency in penetrating hard rock formations. These rigs utilize a rotating drill bit that grinds through the material, often enhanced by the use of drilling fluids that cool the drill and remove cuttings. Understanding the different types of drill bits, such as diamond or carbide-tipped, is crucial for selecting the right tool for the job.

Percussion drilling, on the other hand, relies on a hammering action to break up the ground. This method is particularly effective in loose or unconsolidated materials, where rapid penetration is necessary. Professionals should consider the weight and energy of the hammer and the frequency of blows when evaluating percussion systems.

Auger rigs are typically employed for shallower boreholes and softer soils. This equipment operates by removing soil through a helical screw, making it an excellent choice for applications like soil sampling and environmental studies. When selecting an auger type, factors such as diameter, length, and material should be evaluated based on project needs.

Recent advancements in borehole drilling technology have led to the development of more efficient and environmentally friendly equipment. For instance, the integration of automation and remote sensing technologies has enhanced the accuracy of drilling operations while minimizing the environmental footprint. Professionals should stay informed about these innovations to improve their operational efficiencies and meeting sustainability goals.

In conclusion, understanding borehole drilling equipment is essential for professionals in the engineering and construction sectors. By grasping the fundamental principles and advancements in drilling technology, one can ensure that projects are completed efficiently, safely, and effectively. Adapting to new technologies not only enhances productivity but also contributes to overall project success.

At its core, borehole drilling equipment is designed to penetrate various strata of the Earth, allowing for the extraction of natural resources, the assessment of geological formations, and the establishment of infrastructures like water wells. The equipment comes in a variety of types, including rotary drilling rigs, percussion drilling machines, and auger rigs, each suited for specific soil conditions and project requirements.

Rotary drilling rigs are among the most widely used in borehole drilling due to their efficiency in penetrating hard rock formations. These rigs utilize a rotating drill bit that grinds through the material, often enhanced by the use of drilling fluids that cool the drill and remove cuttings. Understanding the different types of drill bits, such as diamond or carbide-tipped, is crucial for selecting the right tool for the job.

Percussion drilling, on the other hand, relies on a hammering action to break up the ground. This method is particularly effective in loose or unconsolidated materials, where rapid penetration is necessary. Professionals should consider the weight and energy of the hammer and the frequency of blows when evaluating percussion systems.

Auger rigs are typically employed for shallower boreholes and softer soils. This equipment operates by removing soil through a helical screw, making it an excellent choice for applications like soil sampling and environmental studies. When selecting an auger type, factors such as diameter, length, and material should be evaluated based on project needs.

Recent advancements in borehole drilling technology have led to the development of more efficient and environmentally friendly equipment. For instance, the integration of automation and remote sensing technologies has enhanced the accuracy of drilling operations while minimizing the environmental footprint. Professionals should stay informed about these innovations to improve their operational efficiencies and meeting sustainability goals.

In conclusion, understanding borehole drilling equipment is essential for professionals in the engineering and construction sectors. By grasping the fundamental principles and advancements in drilling technology, one can ensure that projects are completed efficiently, safely, and effectively. Adapting to new technologies not only enhances productivity but also contributes to overall project success.

PREVIOUS: