Essential Insights into Borehole Drilling Equipment for Engineering and Construction Professionals

Dec 09,2025

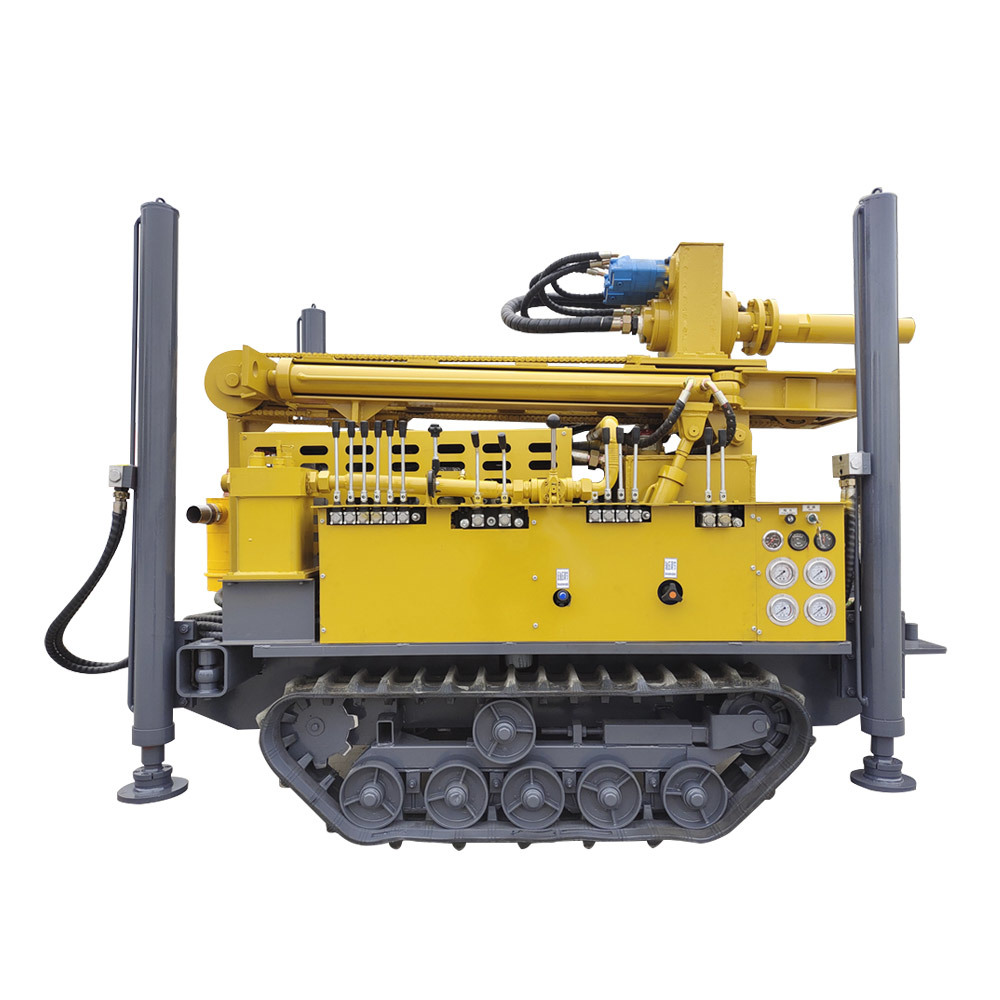

Borehole drilling equipment plays a vital role in various sectors, particularly in engineering and construction. This specialized machinery is essential for creating boreholes—deep, narrow holes in the ground—required for water wells, geothermal heating, mineral exploration, and environmental studies. Understanding the components, types, and advancements in borehole drilling equipment can significantly impact project efficiency and success.

At the core of borehole drilling operations is the drilling rig, which serves as the primary apparatus for creating boreholes. These rigs come in various sizes and configurations, tailored to specific applications. For instance, rotary drilling rigs utilize a rotating drill bit to penetrate the earth, making them suitable for hard rock formations. On the other hand, cable tool drilling rigs, which use a heavy drilling tool suspended on a cable, are often employed for softer ground conditions.

Another crucial component of borehole drilling equipment is the drill bit. The selection of the appropriate drill bit is imperative, as it directly affects the drilling speed and the quality of the borehole. Drill bits are made from various materials, including carbide and diamond, and their designs may vary based on the geological conditions encountered. Understanding the geological makeup of the drilling site can aid in selecting the optimal drill bit, thereby enhancing efficiency.

Advancements in technology have also led to the development of more sophisticated borehole drilling equipment. For instance, the integration of automation and digital technologies has improved drilling precision and reduced human error. This includes the use of telemetry systems that provide real-time data on drilling parameters, allowing operators to make informed decisions quickly. Additionally, advancements in hydraulic systems have led to more powerful and efficient drilling rigs, further enhancing productivity.

Safety is another critical consideration in borehole drilling operations. Modern equipment often incorporates safety features such as automatic shut-off systems and emergency stop buttons. Training and adherence to safety protocols are essential to minimize risks associated with drilling operations.

In conclusion, borehole drilling equipment is a cornerstone of the engineering and construction industries, facilitating various applications ranging from water extraction to environmental assessments. By understanding the components and advancements in borehole drilling technology, professionals can optimize their drilling processes, enhance project outcomes, and ensure safety in operations. As the industry continues to evolve, staying informed about the latest developments in borehole drilling equipment will be paramount for success.

At the core of borehole drilling operations is the drilling rig, which serves as the primary apparatus for creating boreholes. These rigs come in various sizes and configurations, tailored to specific applications. For instance, rotary drilling rigs utilize a rotating drill bit to penetrate the earth, making them suitable for hard rock formations. On the other hand, cable tool drilling rigs, which use a heavy drilling tool suspended on a cable, are often employed for softer ground conditions.

Another crucial component of borehole drilling equipment is the drill bit. The selection of the appropriate drill bit is imperative, as it directly affects the drilling speed and the quality of the borehole. Drill bits are made from various materials, including carbide and diamond, and their designs may vary based on the geological conditions encountered. Understanding the geological makeup of the drilling site can aid in selecting the optimal drill bit, thereby enhancing efficiency.

Advancements in technology have also led to the development of more sophisticated borehole drilling equipment. For instance, the integration of automation and digital technologies has improved drilling precision and reduced human error. This includes the use of telemetry systems that provide real-time data on drilling parameters, allowing operators to make informed decisions quickly. Additionally, advancements in hydraulic systems have led to more powerful and efficient drilling rigs, further enhancing productivity.

Safety is another critical consideration in borehole drilling operations. Modern equipment often incorporates safety features such as automatic shut-off systems and emergency stop buttons. Training and adherence to safety protocols are essential to minimize risks associated with drilling operations.

In conclusion, borehole drilling equipment is a cornerstone of the engineering and construction industries, facilitating various applications ranging from water extraction to environmental assessments. By understanding the components and advancements in borehole drilling technology, professionals can optimize their drilling processes, enhance project outcomes, and ensure safety in operations. As the industry continues to evolve, staying informed about the latest developments in borehole drilling equipment will be paramount for success.