Insights into the Maintenance Needs of Crawler Drilling Rigs

Jan 26,2026

Insights into the Maintenance Needs of Crawler Drilling Rigs

In today's construction and engineering landscape, **crawler drilling rigs** have become indispensable. Their versatility, strength, and ability to operate on uneven terrains make them a go-to choice for various projects. However, like any complex machinery, these rigs require regular maintenance to ensure they function optimally. This article provides an in-depth analysis of the maintenance needs of crawler drilling rigs, outlining techniques, best practices, and solutions to common issues.

Table of Contents

1. Understanding Crawler Drilling Rigs

2. The Importance of Regular Maintenance

3. Essential Routine Maintenance Tasks

- 3.1 Daily Maintenance Checks

- 3.2 Weekly Maintenance Practices

- 3.3 Monthly and Annual Maintenance

4. Common Issues Faced by Crawler Drilling Rigs

5. Advanced Maintenance Techniques

6. The Role of Technology in Rig Maintenance

7. Training and Safety Considerations

8. Conclusion

9. FAQs

Understanding Crawler Drilling Rigs

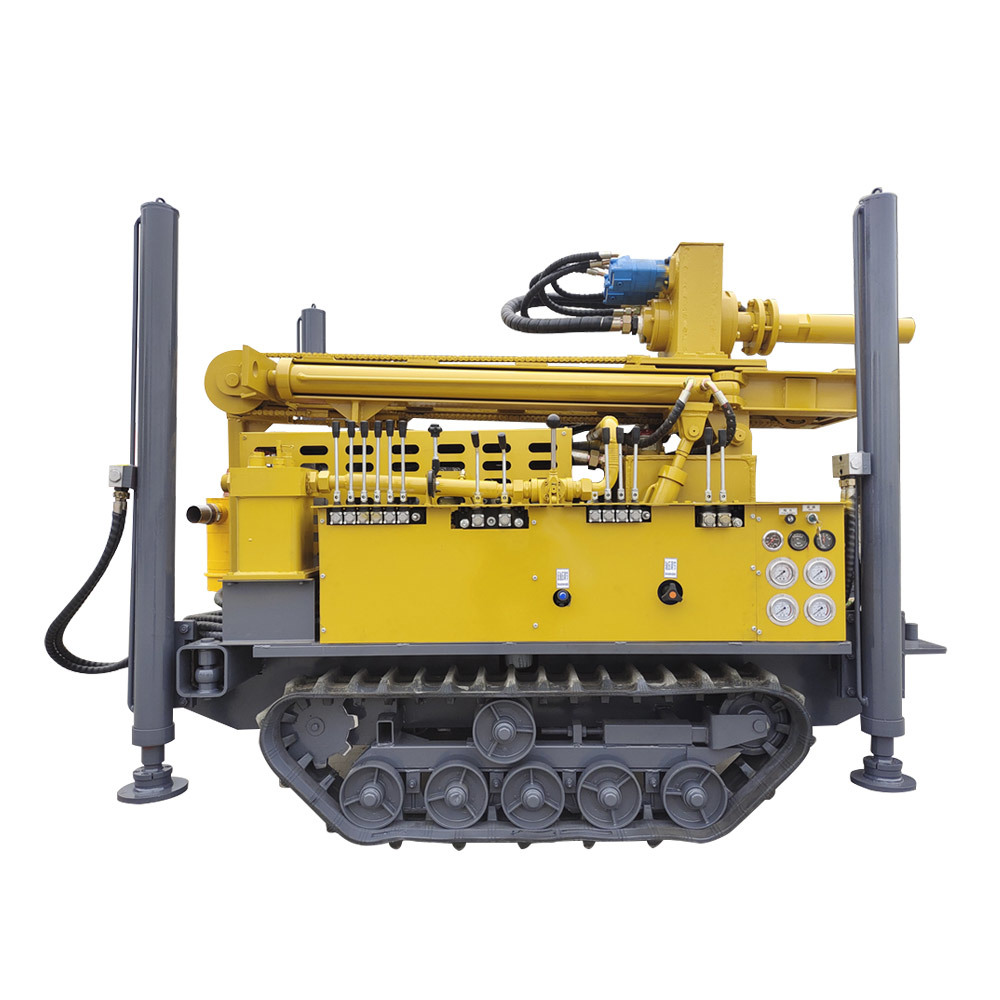

**Crawler drilling rigs** are specialized machines engineered to perform drilling tasks in various environments, including rugged landscapes and construction sites. They are characterized by their **crawler tracks**, which provide superior traction and stability. These rigs are essential for tasks involving geological exploration, foundation drilling, and mining operations. Understanding the mechanics and functions of crawler drilling rigs is crucial in identifying maintenance needs.

The Importance of Regular Maintenance

Regular maintenance is not merely a recommendation but a necessity for crawler drilling rigs. Neglecting maintenance can lead to **increased downtime**, costly repairs, and even accidents on the job site. By prioritizing maintenance, operators can:

- **Extend Equipment Lifespan:** Well-maintained rigs tend to have a longer operational life.

- **Enhance Performance:** Routine checks ensure that the rig operates at peak efficiency.

- **Reduce Operational Costs:** Preventative maintenance can significantly lower repair costs over time.

- **Ensure Safety:** Regular inspections can help identify potential hazards before they escalate.

Essential Routine Maintenance Tasks

To ensure crawler drilling rigs remain in optimal condition, operators must adhere to a structured maintenance schedule. Below, we detail essential routine maintenance tasks.

Daily Maintenance Checks

Daily maintenance checks are fundamental in identifying any immediate issues before they escalate. Typical checks include:

- **Fluid Levels:** Inspect hydraulic fluid, engine oil, and fuel levels to avoid any operational interruptions.

- **Visual Inspections:** Look for signs of wear, leaks, or damage on the rig's surface.

- **Track Condition:** Examine the crawler tracks for wear and tear, ensuring they function effectively.

- **Safety Equipment:** Ensure that all safety equipment and emergency stops are operational.

Weekly Maintenance Practices

Weekly maintenance practices build on daily checks, offering a more comprehensive approach to ensuring the rig's functionality. These practices may include:

- **Filter Replacements:** Check and replace air and oil filters as needed to maintain engine efficiency.

- **Belt and Hose Inspections:** Inspect belts and hoses for wear and replace them if they show signs of deterioration.

- **Battery Maintenance:** Clean battery terminals and ensure all connections are secure and free from corrosion.

Monthly and Annual Maintenance

Monthly and annual maintenance tasks are more in-depth and designed to keep the rig functioning at its best over the long term. Activities include:

- **Complete Oil Changes:** Conduct thorough oil changes as per the manufacturer's guidelines.

- **Hydraulic System Checks:** Inspect the hydraulic system for any signs of leaks or damage.

- **Structural Inspections:** Perform a complete inspection of the frame, booms, and other structural elements for signs of fatigue or cracks.

Common Issues Faced by Crawler Drilling Rigs

Despite the best maintenance efforts, crawler drilling rigs can experience various issues. Recognizing common problems can facilitate timely interventions.

1. Hydraulic System Failures

Hydraulic failures often occur due to leaks or contaminated fluid. Regular inspections and fluid changes can mitigate these risks.

2. Engine Overheating

Overheating may result from low coolant levels or blocked cooling systems. Operators must routinely check coolant levels and ensure that airflow to the radiator is unobstructed.

3. Track Issues

Wear and tear on tracks can lead to slippage and reduced traction. Regular inspections and timely replacements are essential to maintain optimal performance.

Advanced Maintenance Techniques

To further enhance the maintenance of crawler drilling rigs, consider implementing advanced techniques, such as:

1. Predictive Maintenance

Utilizing data analytics and monitoring systems can predict equipment failures before they occur, allowing for proactive maintenance strategies.

2. Scheduled Downtime

Plan maintenance during scheduled downtimes to minimize impact on productivity. This approach ensures that maintenance tasks do not interfere with ongoing projects.

The Role of Technology in Rig Maintenance

Advancements in technology have significantly impacted how maintenance is conducted on crawler drilling rigs. Technologies like **IoT sensors** and **machine learning** can provide real-time data on equipment performance, enabling operators to make informed maintenance decisions.

Training and Safety Considerations

Proper training for personnel operating and maintaining crawler drilling rigs is essential. Training should cover:

- **Equipment Operation:** Understanding how to operate the rig safely and efficiently.

- **Maintenance Protocols:** Knowledge of routine maintenance tasks and schedules.

- **Safety Best Practices:** Ensuring all operators are aware of safety protocols to minimize risks on-site.

Conclusion

Maintaining crawler drilling rigs is crucial for ensuring their longevity, efficiency, and safety in various operational environments. By conducting routine maintenance checks, understanding common issues, and leveraging advancements in technology, operators can enhance performance and reduce costs. Incorporating a proactive maintenance strategy will not only extend the lifespan of the equipment but also contribute to a safer and more productive work environment.

FAQs

1. How often should crawler drilling rigs be serviced?

Routine maintenance checks should be conducted daily, with more comprehensive inspections weekly, monthly, and annually.

2. What are the most common issues faced by crawler drilling rigs?

Common issues include hydraulic system failures, overheating engines, and track wear.

3. How can technology aid in the maintenance of crawler drilling rigs?

Technology, such as IoT sensors, can provide real-time monitoring of equipment performance, allowing for predictive maintenance.

4. What safety training is necessary for operating crawler drilling rigs?

Operators should receive training on equipment operation, maintenance protocols, and safety best practices.

5. What is predictive maintenance, and how does it benefit crawler drilling rigs?

Predictive maintenance uses data analysis to predict potential equipment failures, allowing for timely interventions that minimize downtime and repair costs.

By following these guidelines and insights into the maintenance needs of crawler drilling rigs, organizations can ensure their operational efficiency, safety, and longevity in the field.

PREVIOUS: