Understanding Exploration Drill Rigs: Essential Tools for Modern Engineering and Construction

Jan 29,2026

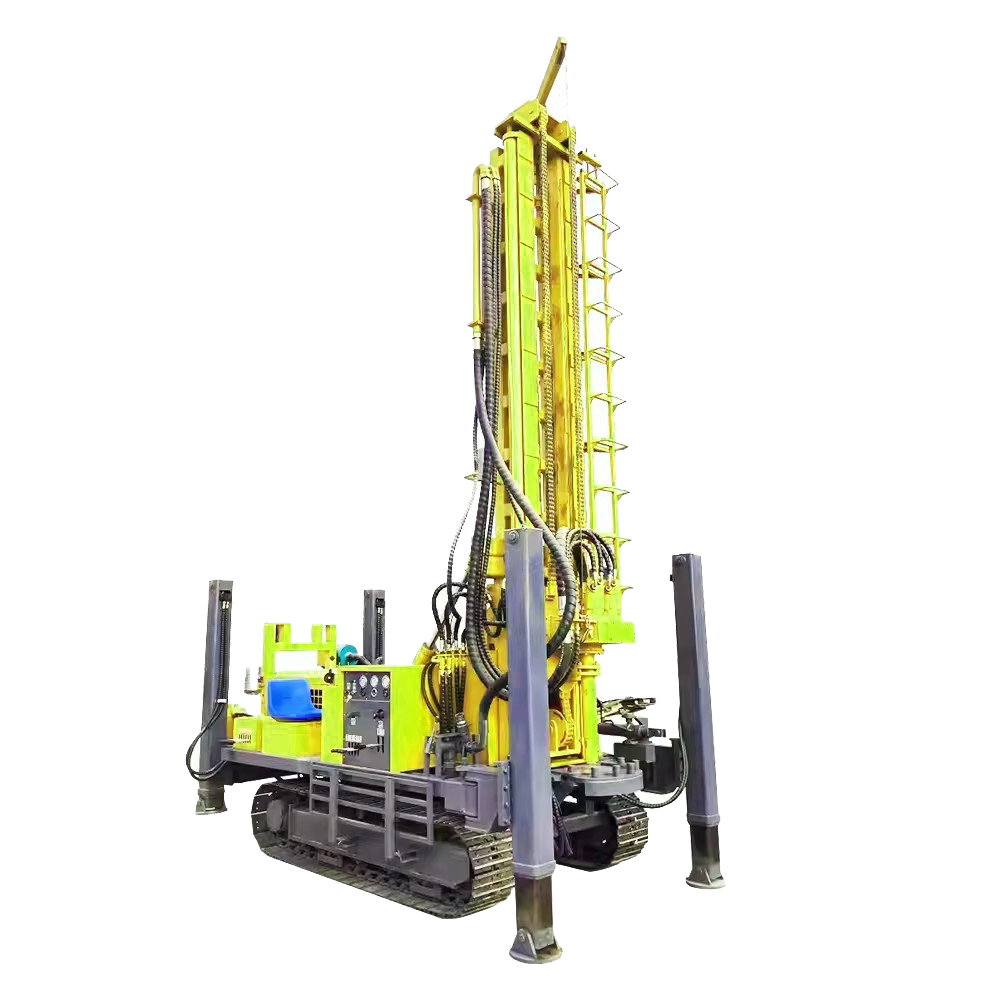

Exploration drill rigs are vital components in the fields of engineering and construction, primarily used for obtaining subsurface data essential for project planning and development. These specialized machines play a key role in mineral exploration, environmental assessments, and geotechnical investigations. By drilling into the ground, they provide invaluable information regarding soil and rock conditions, which is crucial for ensuring the safety and viability of construction projects.

The design of exploration drill rigs varies depending on the specific requirements of the project. Most rigs are equipped with advanced drilling technologies that allow them to operate in a wide range of geological conditions. For instance, rotary drill rigs utilize a rotating drill bit to penetrate the earth, while percussion rigs employ a hammering action to break through hard formations. These diverse drilling methods enable engineers to gather samples from varying depths, providing a comprehensive overview of the subsurface environment.

One of the significant advantages of modern exploration drill rigs is their mobility. Many rigs are designed to be compact and easily transportable, allowing them to access remote and challenging locations. This mobility is particularly beneficial in mineral exploration, where drilling sites may be located in hard-to-reach areas. Additionally, advancements in hydraulic systems have improved the efficiency and effectiveness of these rigs, making them capable of handling tougher terrains and deeper drilling requirements.

In terms of technology, many exploration drill rigs now incorporate automation and data recording systems that enhance operational efficiency. These innovations allow for real-time monitoring of drilling parameters, ensuring that operators can make informed decisions promptly. The integration of geospatial technologies also assists in mapping and analyzing subsurface conditions, facilitating better planning and execution of engineering projects.

Furthermore, environmental considerations are increasingly influencing the design and operation of exploration drill rigs. Many manufacturers are focusing on creating rigs that minimize environmental impact, utilizing eco-friendly fluids for drilling and implementing noise reduction technologies. This focus on sustainability not only helps mitigate environmental damage but also aligns with global trends in responsible resource extraction and construction practices.

In conclusion, exploration drill rigs are indispensable tools in the engineering and construction sectors, providing essential data that informs project development. Their advanced features and technologies greatly enhance the efficiency of subsurface investigations, making them a critical investment for professionals in the industry. Understanding the capabilities and applications of exploration drill rigs is fundamental for engineers and construction managers looking to optimize their project outcomes while adhering to safety and environmental standards.

The design of exploration drill rigs varies depending on the specific requirements of the project. Most rigs are equipped with advanced drilling technologies that allow them to operate in a wide range of geological conditions. For instance, rotary drill rigs utilize a rotating drill bit to penetrate the earth, while percussion rigs employ a hammering action to break through hard formations. These diverse drilling methods enable engineers to gather samples from varying depths, providing a comprehensive overview of the subsurface environment.

One of the significant advantages of modern exploration drill rigs is their mobility. Many rigs are designed to be compact and easily transportable, allowing them to access remote and challenging locations. This mobility is particularly beneficial in mineral exploration, where drilling sites may be located in hard-to-reach areas. Additionally, advancements in hydraulic systems have improved the efficiency and effectiveness of these rigs, making them capable of handling tougher terrains and deeper drilling requirements.

In terms of technology, many exploration drill rigs now incorporate automation and data recording systems that enhance operational efficiency. These innovations allow for real-time monitoring of drilling parameters, ensuring that operators can make informed decisions promptly. The integration of geospatial technologies also assists in mapping and analyzing subsurface conditions, facilitating better planning and execution of engineering projects.

Furthermore, environmental considerations are increasingly influencing the design and operation of exploration drill rigs. Many manufacturers are focusing on creating rigs that minimize environmental impact, utilizing eco-friendly fluids for drilling and implementing noise reduction technologies. This focus on sustainability not only helps mitigate environmental damage but also aligns with global trends in responsible resource extraction and construction practices.

In conclusion, exploration drill rigs are indispensable tools in the engineering and construction sectors, providing essential data that informs project development. Their advanced features and technologies greatly enhance the efficiency of subsurface investigations, making them a critical investment for professionals in the industry. Understanding the capabilities and applications of exploration drill rigs is fundamental for engineers and construction managers looking to optimize their project outcomes while adhering to safety and environmental standards.